Milk transport container MilkCab 500L with electric drive, 4-wheel, 24kW

![]() Professionals recommend - producers prefer!

Professionals recommend - producers prefer!

EAN: 2000005435164

Brand:

Unit: pc

Stock qty: Pre-order

![]()

![]() Delivery time within Estonia for stock items approx. 3-5 working days. NOTE! Due to the rapid price increase, prices for non-stock items may change without prior notice! Standard prices with 24% VAT.

Delivery time within Estonia for stock items approx. 3-5 working days. NOTE! Due to the rapid price increase, prices for non-stock items may change without prior notice! Standard prices with 24% VAT.

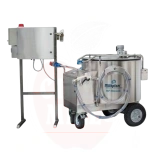

MilkCab 500L Electric Drive Milk Transport Container - 4-Wheel Professional Pasteurization System

MilkCab 500L raw milk pasteurization unit with 4 wheels, electric drive, and 24kW panel is the largest capacity professional milk processing system for larger farms. The device enables the use of "sick" or unmarketable milk through pasteurization at maximum volume, turning losses into significant profits and practically eliminating dependence on milk replacers.

System Configuration and Performance

The system consists of two parts: a wall-mounted water and electric panel (24kW) and a mobile 4-wheeled tank with electric drive. The powerful 24kW panel ensures the fastest heating up to 90-100°C and supplies the heat exchanger with maximum efficiency for milk processing. After pasteurization, the panel cools the milk to feeding temperature.

Electric Drive and Mobility Features

Electric drive is mandatory equipment for models of this capacity. The device is equipped with an 800W electric motor and two 12V 45Ah batteries, ensuring approximately 2.5-3 hours of continuous operation time. Adjustable driving speed and 100W feeding pump allow precise portioning (accuracy 0.25L). Front wheel brake and emergency brake on rear wheels ensure safe operation.

Technical Specifications

- Tank capacity: 500 liters

- Material: Stainless steel AISI 304

- Insulation: 45mm polyurethane foam

- Heating power: 24kW panel

- Electric motor: 800W

- Batteries: 2x 12V 45Ah (2.5-3h operation)

- Feeding pump: 100W (0.25L accuracy)

- Control: 4.3-inch color touchscreen with PLC software

- Wheels: 4-wheel configuration with braking system

- Tank dimensions: 175x117x153cm (260kg)

- Wall panel dimensions: 67x26x72cm (50kg)

- Heat exchanger: Side wall and bottom mounted

Key Product Benefits

Microbiological safety: Pasteurization effectively destroys all microbes and pathogens, protecting calves from infectious diseases.

Economic benefit: Studies show that "sick" milk amounts to a significant portion of farms' total production, and MP MilkCab helps turn this loss into profit and reduce feed costs.

Nutritional value: During pasteurization, milk maintains high concentrations of proteins, fats, salts, phosphorus, and contains minerals, antibodies, and hormones that are better absorbed by animals than regular milk replacers.

Automation and Control

The 4.3-inch color touchscreen's resistive technology ensures high durability and intuitive interface. PLC software enables complete automation of all work processes, and timing function allows farmers to plan milk preparation according to their schedule. Automatic start/stop and temperature control simplify operation.

Transport and Handling

Elevated tank with large wheels and powerful electric drive motor ensure easy transportation even in difficult farm conditions.

Certificates and Standards

Manufactured according to European directives Machinery Directive (MD) 2006/42/EC, Electromagnetic Compatibility Directive (EMC) 2014/30/EU, Pressure Equipment Directive (PED) 2014/68/EU. Strictly complies with standards EN ISO 13857:2019, EN ISO 12100:2010, EN 349:1993+A1:2008, EN 1672-1:2014, EN 1672-2:2005+A1:2009, EN 60204-1:2018, EN 61000-6-1:2007, EN 61000-6-3:2007. Milkplan is certified according to quality management system EN ISO 9001:2018 by RWTUV Systems GmbH.

Optional Equipment

- Stainless steel connections instead of galvanized (for 100-300L models)

- Colostrum pasteurization

- Bottle holder for 6 pcs 150mmx150mm

- Agitation during transport (for 200-300L models)

- Milk inlet connection DN25/DN32

- Individual MilkCab water and electric panel 24kW

- Semi-automatic washing with hose (spray ball included)

- Packaging cost

milk pasteurizer 500L | electric drive milk cart | 4-wheel pasteurization unit | 24kW heating panel | calf feeding equipment | mobile milk processing | farm pasteurization system | raw milk treatment | large capacity milk tank | professional dairy equipment

| Weight (kg) | 310.000000 |

| High (m) | 0 |

| Width (m) | 0 |

| Length (m) | 0 |

.png)