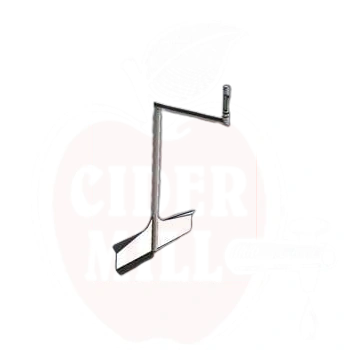

Central Z agitator

![]() Professionals recommend - producers prefer!

Professionals recommend - producers prefer!

EAN: 2000000036267

Brand:

Unit: pc

Stock qty: Pre-order

Delivery time (day): Eritellimustoode / Please contact / Ota yhteyttä

![]()

![]() Delivery time within Estonia for stock items approx. 3-5 working days. NOTE! Due to the rapid price increase, prices for non-stock items may change without prior notice! Standard prices with 24% VAT.

Delivery time within Estonia for stock items approx. 3-5 working days. NOTE! Due to the rapid price increase, prices for non-stock items may change without prior notice! Standard prices with 24% VAT.

Central Z-mixer - efficient industrial mixing equipment

The Central Z-mixer is a powerful industrial device designed for uniform mixing of various fruits, berries, and juice purees. This professional mixing equipment ensures perfect consistency and uniform mass.

Main features

- Stainless steel Z-shaped mixing mechanism

- Adjustable mixing speed

- Capacity up to 500 liters

- Energy-efficient motor

- Easy to clean and maintain

Applications

Ideal solution for:

- Juice industries

- Berry processors

- Fruit processors

- Food industries

The Z-mixer operates quietly and ensures a uniform working process. The device's construction allows efficient mixing even with viscous liquids. Built-in safety systems ensure a safe working environment.

| Weight (kg) | 0.000000 |

| High (m) | 0 |

| Width (m) | 0 |

| Length (m) | 0 |

.png)