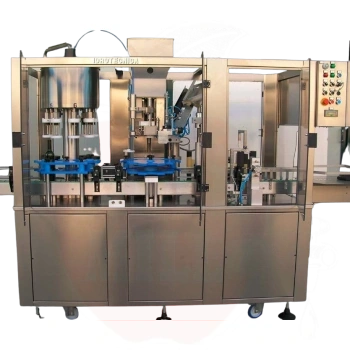

Monoblock R8 TC for beer

![]() Professionals recommend - producers prefer!

Professionals recommend - producers prefer!

EAN: 2000000011431

Unit: pc

Stock qty: Pre-order

Delivery time (day): Eritellimustoode / Please contact / Ota yhteyttä

![]()

![]() Delivery time within Estonia for stock items approx. 3-5 working days. NOTE! Due to the rapid price increase, prices for non-stock items may change without prior notice! Standard prices with 24% VAT.

Delivery time within Estonia for stock items approx. 3-5 working days. NOTE! Due to the rapid price increase, prices for non-stock items may change without prior notice! Standard prices with 24% VAT.

Automatic 8-head filling machine for carbonated beverages

Perfect solution for small and medium-sized soft drink manufacturers - a compact monoblock filling machine. The device is equipped with 8 precise filling nozzles on a rotating base, ensuring uniform and rapid filling process.

Main features:

- Automatic filling system for lightly carbonated drinks

- 8 filling nozzles ensure optimal production speed

- Integrated automatic capping system for DN26mm caps

- Vibrating cap feeding system for smooth operation

- Bottle transport line with collection system

Technical information:

- Compact monoblock construction

- Rotating filling base ensures uniform filling

- Suitable for filling various soft drinks

- Easy to clean and maintain

The machine is an ideal choice for manufacturers who need a reliable and efficient filling solution. Thanks to its compact design, it's also suitable for facilities with limited production space.

Keywords: filling machine, soft drink filler, monoblock, automatic filler, carbonated beverage filling, 8-head filler, bottle filling, capping system

beer filling machine | carbonated beverage filler | 8-head monoblock filler | automatic bottling equipment | brewery filling system | rotary bottle filler | craft beer bottling machine | carbonated drink production | small brewery equipment | monoblock filling line

| Weight (kg) | 0.000000 |

| High (m) | 0 |

| Width (m) | 0 |

| Length (m) | 0 |

.png)