Manual stainless steel counter pressure filler

![]() Professionals recommend - producers prefer!

Professionals recommend - producers prefer!

EAN: 5420069822439

Brand:

Unit: pc

Stock qty: Pre-order

![]()

![]() Delivery time within Estonia for stock items approx. 3-5 working days. NOTE! Due to the rapid price increase, prices for non-stock items may change without prior notice! Standard prices with 24% VAT.

Delivery time within Estonia for stock items approx. 3-5 working days. NOTE! Due to the rapid price increase, prices for non-stock items may change without prior notice! Standard prices with 24% VAT.

92,75 €/Kg

Video

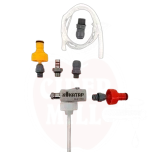

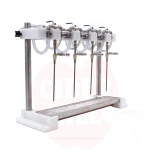

Professional Manual Valve for Liquid Filling

High-quality manual valve system specifically designed for precise filling of pre-pressurized liquids. Ideal for filling beer and other carbonated beverages.

Technical Specifications

- Bottle opening diameter: 14-20mm

- Minimum bottle height: 220cm

- Connection tube inner diameter: 5-6mm

Main Benefits

- Foam-free filling

- Quick filling process

- Easy installation

- Three operating modes: CO2 inlet, liquid inlet, closed position

Complete System

For a fully functional filling system, you additionally need:

- Pressure tank

- CO2 cylinder

- Regulator

- Connection hoses with fittings

We also offer complete system assembly service - contact us for a personalized solution.

Keywords: filling device, beer valve, beverage industry, manual valve, CO2 valve, bottle filler, filling system, liquid filling

| Weight (kg) | 0.690000 |

| High (m) | 0.065 |

| Width (m) | 0.175 |

| Length (m) | 0.485 |

.png)