Counter Pressure Bottle Filler NukaTap, for bottles

![]() Professionals recommend - producers prefer!

Professionals recommend - producers prefer!

EAN: 9388866621760

Brand:

Unit: pc

Stock qty: 14

![]()

![]() Delivery time within Estonia for stock items approx. 3-5 working days. NOTE! Due to the rapid price increase, prices for non-stock items may change without prior notice! Standard prices with 24% VAT.

Delivery time within Estonia for stock items approx. 3-5 working days. NOTE! Due to the rapid price increase, prices for non-stock items may change without prior notice! Standard prices with 24% VAT.

115,72 €/Kg

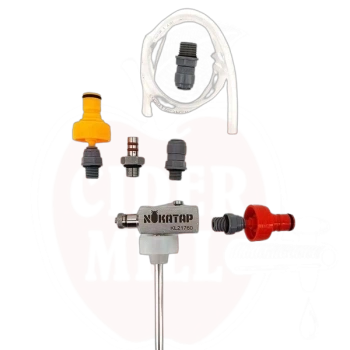

NukaTap Counter Pressure Bottle Filler - Professional Beer Filling Equipment

NukaTap counter pressure filler is a professional device made entirely of stainless steel, enabling beer filling from kegs to bottles while perfectly preserving the drink's taste, aroma, and carbonation. The device is compatible with all standard beer taps with an internal spout diameter of 10.0 mm or 3/8" universal thread.

Main Features and Benefits

This compact and durable device includes:

- Telescopic tubing for quick cleaning

- Integrated counter pressure relief valve for precise control

- Quick-disconnect carbonation cap

- Duotight fittings for beer line connection

Technical Information and Usage

The counter pressure filler operates on the pressure difference principle:

- Bottle is filled with CO2 to keg pressure

- Beer flows into the bottle maintaining carbonation

- Pressure remains balanced throughout the filling process

Compatibility and Maintenance

The device is compatible with most forward-sealing taps, including:

- NukaTap SS models

- NukaTap FC models

- Perlick taps

Thanks to its stainless steel construction, the device can be cleaned with various chemicals, ensuring long-term durability and hygiene.

The NukaTap counter pressure filler is an ideal choice for both home beer bottling and professional use, maintaining beer quality and taste throughout the entire filling process.

Keywords: beer filler, counter pressure filler, beer bottler, beer equipment, carbonation device, NukaTap, bottle filler, beer accessories

counter pressure bottle filler | beer bottling equipment | NukaTap filler | stainless steel bottle filler | keg to bottle filler | carbonation preserving filler | professional beer bottling | craft beer bottling equipment

| manufacturer_address | Biezenkamp 21 a (6691 EJ), in Gendt, Denmark |

| manufacturer_email | info@kegland.eu, wholesale@kegland.eu |

| manufacturer_name | KegLand EU B.V. |

| Weight (kg) | 0.388000 |

| High (m) | 0.045 |

| Width (m) | 0.13 |

| Length (m) | 0.185 |

.png)