Hop dosing unit with flow-through, hop infuser

![]() Professionals recommend - producers prefer!

Professionals recommend - producers prefer!

EAN: 20000000541040

Brand:

Unit: pc

Stock qty: Pre-order

![]()

![]() Delivery time within Estonia for stock items approx. 3-5 working days. NOTE! Due to the rapid price increase, prices for non-stock items may change without prior notice! Standard prices with 24% VAT.

Delivery time within Estonia for stock items approx. 3-5 working days. NOTE! Due to the rapid price increase, prices for non-stock items may change without prior notice! Standard prices with 24% VAT.

1552,94 €/Kg

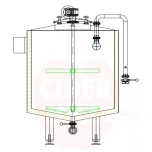

Hop Dosing Unit with Flow-Through, Hop Infuser

The Hop Missile can be used both in Hop Back mode and as a Flow-through hop infuser. The difference lies in routing the wort back to the kettle through the Hop Missile OR directing the wort straight to the fermenter through the Hop Missile as a Flow-through hop infuser. Both methods let you participate in an exciting process that gives your beer additional aroma and flavor enhancement using this novel hop addition method. This is essential equipment for all home hop growers to showcase the best qualities of their harvest.

Technical Specifications

- Withstands pressure up to 2.8 bar (40psi)

- Holds 85g of whole hop cones/flowers when used in Hop Back mode

- Holds 115g of whole hop cones/flowers when used as Flow-through hop infuser

- 100% 304 stainless steel construction with heat-resistant food-grade EPDM gaskets

- Fully enclosed system allows for easy and low-maintenance monitoring on brew day

Recommended Connections

We recommend using camlock connections for inlet and outlet. Specifically female 1/2" BSP to male Camlock.

Other Uses

This Hop Missile can also be used as a flow-through filter to filter out most of the hop material before reaching the fermenter. Fill the device with 80g of rice hulls and run the wort through!

Important Notice

When using pelleted hops or if you have a large amount of sediment and debris, it may compress and obstruct the flow through the Hop Missile. To prevent this, it's recommended to install a pre-filter in the kettle to prevent excess material from entering the hopback device. We strongly recommend using rice hulls with hop pellets to facilitate wort passage through the Hop Missile.

Operating Principle

The Hop Missile is designed to enhance beer hop aroma and flavor as wort moves from kettle to fermenter. The device allows wort to pass through a hop layer in a controlled manner, extracting more aroma and flavor components into the beer without adding unnecessary bitter compounds.

hop missile | hop back | flow-through hop infuser | beer brewing equipment | hop dosing unit | homebrewing | stainless steel hop infuser | wort filtering | craft beer | brewing accessories

| Weight (kg) | 0.085000 |

| High (m) | 0 |

| Width (m) | 0 |

| Length (m) | 0 |

.png)