Mixer Fimar 25/CNS 32L 1.5kw/230V

![]() Professionals recommend - producers prefer!

Professionals recommend - producers prefer!

EAN: 2000000005256

Unit: pc

Stock qty: Pre-order

Delivery time (day): Eritellimustoode / Please contact / Ota yhteyttä

![]()

![]() Delivery time within Estonia for stock items approx. 3-5 working days. NOTE! Due to the rapid price increase, prices for non-stock items may change without prior notice! Standard prices with 24% VAT.

Delivery time within Estonia for stock items approx. 3-5 working days. NOTE! Due to the rapid price increase, prices for non-stock items may change without prior notice! Standard prices with 24% VAT.

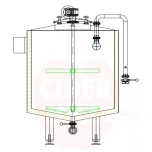

Professional Fimar Dough Mixer 32L - Industrial Baking Equipment

Discover the professional dough mixer by Italian manufacturer Fimar, designed for industrial use in bakeries and large kitchens. The stainless steel 32-liter mixing bowl ensures maximum productivity and hygiene.

Main Features:

- Productivity: 75 kg/h (one work cycle 25 kg)

- Powerful 1500W/230V motor

- Lift-up stainless steel working element

- Large mixing bowl dimensions: ø 400x260h mm

- Device dimensions: 780x430x730-1240h mm

- Device weight: 107 kg

Customizable Options:

- Digital or manual timer for precise timing

- 2-speed motor (3F/400V, 1.5/1.1kw)

- Movable on wheels or stainless steel trolley-surface

- Stainless steel safety grid or handles for container

- Built-in motor overheating protection

The Fimar dough mixer is an ideal choice for bakers and food industries who value reliability, safety, and quality. The device is designed to ensure maximum user comfort and reliability in daily industrial environment.

Keywords: dough mixer, fimar, industrial baking equipment, kitchen equipment, bakery industry, food industry equipment, commercial kitchen equipment, 32l mixer

professional dough mixer | Fimar mixer 32L | industrial bakery equipment | stainless steel dough mixer | commercial planetary mixer | bakery dough kneader | 32 liter mixing bowl | Italian bakery equipment | professional kitchen mixer | industrial mixing machine

| Weight (kg) | 107.000000 |

| High (m) | 0 |

| Width (m) | 0 |

| Length (m) | 0 |

.png)